MEWP (Mobile Elevated Work Platforms)

CSA (ISO) has updated and changed standards regarding Mobile Elevated Work Platforms (MEWP) also known as EWP/AWP- Scissor-lift/ Boom-lift/ Personnel Lift / Genie / JLG training etc.

The CSA (ISO) new standards that affect our clients directly are:

CAN/CSA-B354.8:17 Mobile elevating work platforms — Operator (driver) training (ISO 18878:2013, MOD)

CAN/CSA-B354.7:17 Mobile elevating work platforms — Safety principles, inspection, maintenance and operation (ISO 18893:2014, MOD)

Touchback Safety has updated our OH&S Compliant MEWP program to meet the new CSA standards of Primary Training (CSA B354.8:17 -6.1) and Practical Evaluation (CSA B354.8:17 -6.3)

WHEN REGISTERING: be aware of the specific course you need. If you are working on an Oil Sands Site or associated with a BTA Union, ESC certifications are mandatory. Always verify with your worksite or employer to confirm their requirements.

OHS Compliant MEWP :

Includes both Boom and Scissor Lift Practical (Group A & B Type 3).

Valid Fall Protection certificate is a prerequisite

Cost for OHS Compliant MEWP is $195.00

We can provide onsite OHS Compliant MEWP courses for any Group or Type; however, you must specify the type of MEWP(s) for which you need certification. In the Edmonton area, a minimum of six participants is required; for locations outside of Edmonton, travel costs will be incurred.

ESC MEWP program

Practical Portion of this course is completed on a Boom lift (Group B – Type 3)

Cost for ESC MEWP course $195.00

*IMPORTANT :Registration for this course requires an ESC Fall Protection certificate. No other certificates, including BTATS, will be accepted. Should you register without the appropriate Fall Protection certificate, you will be ineligible to attend the course and the fee will be non-refundable.

____________________________________________________________________

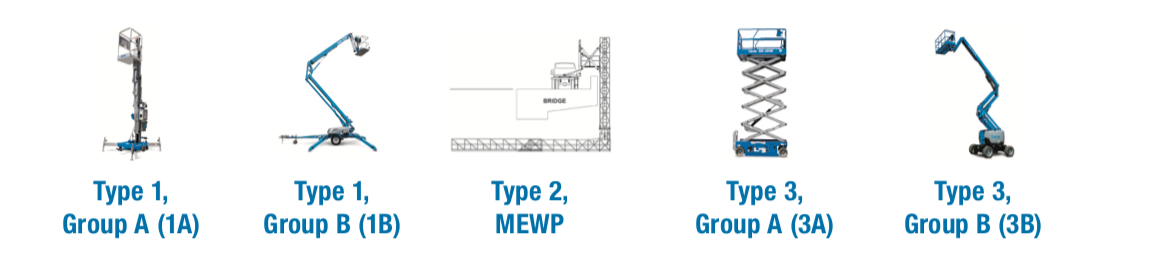

NEW CLASSIFICATIONS of MEWPs

Group A – centre of the work platform remains within the perimeter of the chassis at all times

Scissor lifts – Vertical lifts

Group B – Center of the work platform can be positioned beyond the chassis

Boom lifts

Each Group is further broken down into types

Type 1– Can travel only in the stowed position and must be moved manually.

Example: Personnel / Push around lifts

Type 2 – Can travel elevated but is controlled from a point of the chassis

Example: Under-bridge inspection machine

Type 3 – Have controls on the work platform and can be driven elevated

Example: Booms / Scissors

NEW STANDARD INFORMATION:

These new standards affect all users, owners, operators, and supervisors. The new standards now place more responsibility on the MEWP user/owner. OH&S regulations require supervisors to be competent in their ability to supervise workers using MEWP’s. NEW CSA standards are not requiring supervisors to be trained (this is a new ANSI standard), however they require an **examiner to complete *familiarization and competency with the worker.

Once the worker (operator) has completed their training they will be required to complete a Familiarization and competency check with their employer’s designated examiner for each specific make and model of MEWP that falls under the classification their certificate indicates.

Feel free to use our Sample forms or for reference to create your own with the provided links below.

*CSA B354.8:17 -6.2 – Familiarization

Before being authorized to operate a make/model of MEWP the operator shall receive familiarization by a qualified person in:

- Location of manual

- The manufactures specific warnings and instructions

- The specific control functions

- Function of each specific safety feature

- Operating characteristics

- The verification of annual inspection

**CSA B354.8.:17 (7.3) Examiner- The MEWP examiner shall be a qualified person to provide familiarization (See Clause6.2) and practical evaluation (see clause 6.3). An examiner is not required to be a qualified person to deliver operator theory.

Examiner’s knowledge and experience shall include, at a minimum, the following:

- Experience as a qualified MEWP operator in the classifications for which they offer evaluations;

- Knowledge of the practical evaluation process;

- The ability to demonstrate and evaluate trainees on a pre start inspections;

- Knowledge on risk assessments and workplace inspections; and

- Knowledge of the safe use requirements defined in CSA-B357.7

Occupant Training (CSA B354.8:17 6.5) The MEWP operator shall provide instructions and ensure that the occupants have a basic level of knowledge to work safely on the MEWP

The occupant instruction shall include, as a minimum, the following:

- Use fall protection and use of anchorage

- Factors affecting stability

- Safe use of accessories

- Site specific work procedures for use of the MEWP

- Avoidance of hazards as to the risk assessment

- General knowledge of purpose and functions (controls, features, and devices including emergency shutdown and lowering procedures to bring the MEWP down to the ground or stowed position.)

- The manufactures warnings related to work activity

- Location of the operator’s manual

Training / Retraining (CSA B354.8:17 7.4)

The operator shall be trained or retrained as necessary to keep the level of proficiency at an acceptable level.

Biggest question we are being asked: Do our current operators need to be retrained? – This depends on their previous training, and how often they operate the equipment. Touchback Safety courses have always included Manufacturer requirements, OH&S regulations and ANSI, which include most of these new standards.

Examples of situations when retraining is necessary include, but not limited to:

- expiration of valid training

- deterioration of proficiency

- following an accident or near miss while operating or using a MEWP

- a condition on the workplace changed in a manner that could affect he safe operation of the MEWP

- new MEWP technologies and working methods.

Additional info for all MEWP users:

- All MEWP users must develop a risk assessment and site safety plan

- There must be someone on the ground who can act as an operator in the event of an unexpected malfunction or emergency.

- Maintenance personnel must be trained on any new features, such as tilt sensor, wind speed sensor, and load limit alarm. Attendance personnel must conduct annual inspections as well conducting an inspection on MEWP’s that have been out of service for more than 3 months.

- New Aerial lifts will be required to have sensors that sound an alarm and prevent the machine from operating when the safe load limit is exceeded, must also include a tilt sensor that triggers an alarm and prevents movement of the chassis or work platform when a certain level of slope is exceeded.

- Chains to close off entrances to the work platform will no longer be permitted; MEWPS will have to have a gate, complete with toe guards